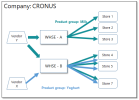

This is the most common approach in retail, where purchased items are routed via a warehouse to the stores. The warehouse acts as a distribution center and buffer to ensure replenishment to the stores.

Replenishment Journals are used to calculate Purchase Order and Transfer Order proposals for Replenishment - they need to be set up according to the used item flow. LS Central supports two approaches to cover these item flows:

- Without Cross Docking

- With Cross Docking

In both approaches the items are delivered to the warehouse first. In the approach with cross docking, the destination store is already known and a Transfer Order is created together with the original Purchase Order. A goods receipt needs to be performed for the Purchase Order before the shipment of the Transfer Order can be started.

Goal

The goals of this step:

- Get a detailed understanding of the retailer's item-flow approach

- Identify different item-flows for different product groups and stores

- Create an item-flow drawing

- Set up Replenishment Templates and Journals in LS Central.

Key questions / considerations

Item Flow related questions:

- Are all items for all stores purchased to the warehouses first?

- If not:

- Specific product groups or items?

- Items from a specific vendor?

- Which stores?

If there is more than one warehouse:

- How are stores assigned to warehouses?

- Geographically

For example:- stores in the north are replenished from a warehouse in the north.

- stores in the south are replenished from a warehouse in the south.

- Product groups

For example:- warehouse A holds cooled/frozen items.

- warehouse B holds all other items.

- stores receive frozen items from warehouse A and all other items from warehouse B.

- Combination

For example:- warehouse A (in the north) holds cooled/frozen goods.

- warehouse B (in the north) holds all other goods.

- warehouse C (in the south) holds all goods.

- stores in the north are replenished from warehouse A or B, depending on the product.

- stores in the south are replenished from warehouse C.

- Geographically

Output

-

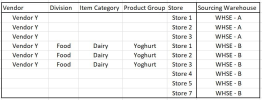

Item-flow drawing and list (see example here):

-

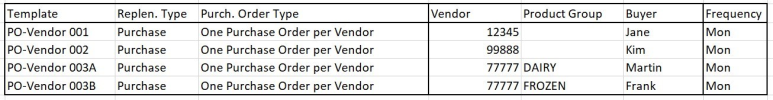

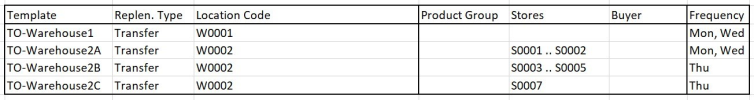

Template lists (without Cross Docking).

-

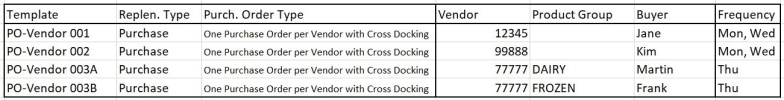

Template lists (with Cross Docking):

LS Central setup considerations

Replenishment Setup

One warehouse location must be set up as a default warehouse location in the field Default Central Warehouse on the Replen. Setup page.

All stores will be replenished from this warehouse unless defined differently in the Replen. From Warehouse page.

For more details see Warehouse.

Replenishment rules for non-default warehouses

For the non-default warehouses, explicit definitions need to be set up: which store will be replenished by which warehouse for which items.

The item flow drawing or list is used to set up the dependencies in the Replen. From Warehouse page.

Replenishment Templates and Journals (without Cross Docking)

Replenishment Journals are used to calculate Purchase Order and Transfer Order proposals for Replenishment.

Each Journal has a Template and a Batch:

- The Template defines what and how the Journal should calculate - it defines the item flow and provides filters for items, stores, vendors, and more.

- The Batch defines when the Journal should be calculated.

For the Vendor to Warehouse approach without Cross Docking you create Purchase and Transfer Templates with the following settings:

Purchase Templates

- Replenishment Type is set to Purchase.

- Purchase Order Type is set to One Purchase Order per Vendor to define this item flow approach.

- Location Code is set to the warehouse for which Purchase Order proposals should be calculated.

Transfer Templates

- Replenishment Type is set to Transfer.

- Location Code is set to the warehouse from which Transfer Order proposals should be calculated for the stores.

If you detect in the analysis that not all items or stores are using this approach, you must filter the Template to the desired items and locations. The Template provides filters for:

- Vendors

- Item based filters (Division, Item Category, Product Group, Special Group, ...)

- Store based filters.

The calculation frequency is set up in the Replenishment Batch. If stores are replenished on different days, then it is best practice to create multiple Templates that contain stores with the same interval.

For example: stores A and B are replenished on Monday and Thursday, store C is replenished on Wednesday only. You would create two Templates with filters for the stores and set up the batches to reflect the frequency.

Replenishment Templates and Journals (with Cross Docking)

Replenishment Journals are used to calculate Purchase Order and Transfer Order proposals for Replenishment.

Each Journal has a Template and a Batch:

- The Template defines what and how the Journal should calculate - it defines the item flow and provides filters for items, stores, vendors, and more.

- The Batch defines when the Journal should be calculated.

For the Vendor to Warehouse approach with Cross Docking approach you create Purchase Templates only - with the following settings:

Purchase Templates

- Replenishment Type is set to Purchase.

- Purchase Order Type is set to One Purchase Order per Vendor with Cross Docking to define this item flow approach.

- Location Code is set to the warehouse for which Purchase Order proposals should be calculated.

Transfer Templates

- No Transfer Templates are created because the Purchase Template will create Purchase Orders and Transfer Orders.

If you detect in the analysis that not all items or stores are using this approach, you must filter the Template to the desired items and locations. The Template provides filters for:

- Vendors

- Item based filters (Division, Item Category, Product Group, Special Group, ...)

- Store based filters.

The calculation frequency is set up in the Replenishment Batch. If stores are replenished on different days, then it is best practice to create multiple Templates that contain stores with the same interval.

For example: stores A and B are replenished on Monday and Thursday, store C is replenished on Wednesday only. You would create two Templates with filters for the stores and set up the batches to reflect the frequency.

For more information see:

If multiple buyers or buyer groups work with Replenishment Journals and Templates it is good practice to split the results of the Replenishment calculation into groups that follow the department structure. This is done by filtering the Replenishment Templates.

For example:

- For the purchase part, Templates are very often split into individual Templates per vendor. Furthermore, Buyer and Buyer Groups are also a separation criteria.

- For the transfer part, Templates are very often split by stores or store groups that are replenished in the same interval. Buyer and Buyer Groups are also a separation criteria.

Go back to: